LIQUID RING VACUUM PUMPS are constantly becoming more important in modern plant production processes. Their design and principle of operation offers many advantages over other types of rotary gas pumps. Liquid Ring Vacuum Pumps can be used on a very large scale for widely divergent applications.

Click to view Hi-Vac Pump tables below:

- Capacity Tables GDH Series 50Hz

- Capacity Tables GDH Series 60Hz

- Capacity Tables GDM Series 50Hz

- Capacity Tables GDM Series 60Hz

Operating Principle

Operating Principle

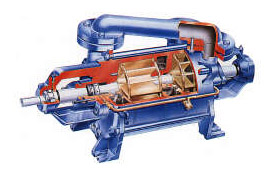

The diagram above shows a cross section of the Liquid Ring Vacuum Pump. It operates on the rotary liquid piston principle, the shaft and the impellers being the only moving parts.

The shaft and impeller assembly is mounted eccentrically relative to the pump casing. As the impeller rotates the service liquid ( which is continually supplied to the pump ), is forced outwards by centrifugal force to form a liquid ring revolving concentric to the pump casing.

Because of the eccentric position of the impeller, the liquid ring will move towards and away from the shaft, resulting in a liquid piston action which displaces the air or gases between the spaces of the impeller blades.

As the impeller rotates, the liquid is thrown out by centrifugal force and air is drawn in through the suction port. After the suction port is passed, the service liquid is forced back into the spaces between the impeller blades, gradually compressing the air or gases. When the spaces between the impeller blades reach the discharge point, the liquid ring will force the air compressed between the blades into the discharge port.

As the impeller rotates, the liquid is thrown out by centrifugal force and air is drawn in through the suction port. After the suction port is passed, the service liquid is forced back into the spaces between the impeller blades, gradually compressing the air or gases. When the spaces between the impeller blades reach the discharge point, the liquid ring will force the air compressed between the blades into the discharge port.

Liquid Ring Vacuum Pumps offer the following advantages:

1. High Vacuum. Up to 25mm Hg absolute, and higher (with other service liquid).

2. Long Life and Low Maintenance Cost. The impellers and shaft are the only moving parts. The impellers have no contact with the casing. There are no sliding vanes or valves.

3. Vibration-free and Noiseless Operation. Rugged construction and absence reciprocating parts ensure vibration-free and noiseless operation.

4. Non-pulsation Gas Flow.

5. No Internal Lubrication.

6. Liquid and Vapour Handling. Liquid Ring Vacuum Pumps are capable of handling large quantities of vapour. Small amounts of liquid drawn in from the system will pass through the pump without causing damage.

7. Low Starting Torque.

8. Different Service liquids may be used.

9. Materials of Construction. Pumps can be constructed from a wide range of materials to suit corrosive conditions.

10. Delivery of Absolutely Oil-free Air. When unit is used as a compressor.

The capacities below are based on dry air at 20°c and seal water at 15°c. The barometric pressure is 760mm hg abs. Tolerance 10%

Capacity Tables

| Model GDM |

Motor kW |

Speed rev/ min |

Flange conn mm |

Service liquid conn |

260 TORR |

160 TORR |

80 TORR |

60 TORR |

40 TORR |

30 TORR |

25 TORR |

Service liquid flow rate l/min |

|||||||

| m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | ||||||

| 20/2 | 1,5 | 2800 | 32 | 3/8" BSP | - | - | 39 | 1,35 | 37 | 1,3 | 34 | 1,3 | 27 | 1,3 | 18 | 1,3 | - | - | 5,9 |

| 30 | 3 | 1450 | 40 | ½" BSP | 57 | 2,24 | 57 | 2,24 | 52 | 2,24 | 49 | 2,24 | 42 | 2,24 | 33 | 2,24 | 25 | 2,24 | 12 |

| 60 | 4 | 1450 | 40 | ½" BSP | 108 | 2,98 | 108 | 2,98 | 105 | 2,83 | 100 | 2,76 | 84 | 2,69 | 72 | 2,61 | 54 | 2,61 | 14 |

| 80 | 4 | 1450 | 40 | 3/4" BSP | 126 | 3,58 | 132 | 3,51 | 150 | 3,78 | 145 | 3,13 | 120 | 2,98 | 90 | 2,83 | 72 | 2,76 | 19 |

| 100 | 5,5 | 1450 | 40 | 3/4" BSP | 146 | 4,18 | 145 | 4,18 | 180 | 3,88 | 180 | 3,88 | 155 | 3,8 | 125 | 3,73 | 100 | 3,73 | 23 |

| 150 | 11 | 1450 | 50 | 1" BSP | 270 | 7,46 | 290 | 7,31 | 280 | 6,94 | 270 | 6,68 | 220 | 6,79 | 190 | 6,71 | 165 | 6,71 | 32 |

| 200 | 11 | 1450 | 50 | 1" BSP | 330 | 9,33 | 360 | 8,95 | 350 | 8,21 | 340 | 7,83 | 300 | 7,53 | 240 | 7,53 | 200 | 7,46 | 37 |

| 250 | 11 | 1450 | 50 | 1" BSP | 390 | 10,44 | 440 | 10,07 | 440 | 9,4 | 420 | 9,25 | 360 | 8.95 | 290 | 8,95 | 225 | 8,8 | 46 |

| 300 | 18,5 | 1450 | 80 | 1¼" BSP | 510 | 14,92 | 540 | 14,92 | 510 | 14,55 | 480 | 14,55 | 420 | 14,17 | 330 | 14,17 | - | - | 75 |

| 450 | 30 | 1450 | 80 | 1¼" BSP | 720 | 22,38 | 780 | 20,89 | 750 | 20,14 | 690 | 19,4 | 510 | 19,4 | 390 | 18,65 | - | - | 89 |

| 500 | 30 | 960 | 100 | 2" BSP | 840 | 24 | 900 | 24 | 870 | 22 | 840 | 22 | 780 | 21 | 660 | 21 | - | - | 96 |

| 750 | 37 | 960 | 100 | 2" BSP | 1200 | 34 | 1350 | 34 | 1320 | 30 | 1230 | 29 | 1020 | 28 | 800 | 28 | - | - | 110 |

| 950 | 45 | 960 | 100 | 2" BSP | 1320 | 37 | 1500 | 37 | 1700 | 34 | 1620 | 33 | 1320 | 31 | 1080 | 30 | - | - | 120 |

| 1200 | 75 | 720 | 150 | 2½" BSP | 1920 | 58 | 2100 | 57 | 2100 | 48 | 1980 | 46 | 1680 | 44 | 1320 | 43 | - | - | 166 |

| 1500 | 75 | 720 | 150 | 2½" BSP | 2280 | 70 | 2500 | 69 | 2650 | 60 | 2500 | 57 | 2200 | 55 | 1740 | 54 | - | - | 191 |

| 1800 | 90 | 720 | 150 | 2½" BSP | 2630 | 82 | 3000 | 83 | 3200 | 72 | 3100 | 69 | 2800 | 66 | 2200 | 64 | - | - | 232 |

| Model GDH |

Motor kW |

Speed rev/ min |

Flange conn mm |

Service liquid conn |

160 TORR |

110 TORR |

80 TORR |

60 TORR |

40 TORR |

30 TORR |

25 TORR |

Service liquid flow rate l/min |

|||||||

| m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | ||||||

| 20/2 | 2,2 | 3400 | 32 | 3/8" BSP | 53 | 1,9 | 53 | 1,9 | 49 | 1,8 | 44 | 1,8 | 32 | 1,8 | 20 | 1,8 | - | - | 7,5 |

| 30 | 3 | 1750 | 40 | ½" BSP | 69 | 2,76 | 68 | 2,76 | 64 | 2,76 | 56 | 2,83 | 45 | 2,83 | 34 | 2,83 | 25 | 2,83 | 15 |

| 60 | 4 | 1750 | 40 | ½" BSP | 127 | 3,65 | 126 | 3,65 | 114 | 3,6 | 102 | 3,5 | 84 | 3,43 | 71 | 3,43 | 55 | 3,36 | 19 |

| 80 | 5,5 | 1750 | 40 | 3/4" BSP | 166 | 4,85 | 168 | 4,4 | 174 | 4,4 | 166 | 4,4 | 146 | 4,33 | 123 | 4,26 | 101 | 4,18 | 22 |

| 100 | 7,5 | 1750 | 40 | 3/4" BSP | 195 | 5,97 | 220 | 5,74 | 220 | 5,7 | 209 | 5,67 | 186 | 5,59 | 161 | 5,55 | 135 | 5,52 | 25 |

| 150 | 11 | 1750 | 50 | 1" BSP | 333 | 10,44 | 338 | 10,3 | 331 | 10 | 312 | 9,84 | 261 | 9,7 | 224 | 9,55 | 199 | 9,55 | 38 |

| 200 | 15 | 1750 | 50 | 1" BSP | 420 | 12,3 | 420 | 11,6 | 413 | 11,4 | 405 | 11,2 | 301 | 11 | 272 | 10,6 | 207 | 10,4 | 45 |

| 250 | 15 | 1750 | 50 | 1" BSP | 520 | 14,17 | 526 | 13,8 | 520 | 13,4 | 492 | 13,1 | 400 | 13,1 | 314 | 13,05 | 237 | 12,5 | 50 |

| 300 | 22 | 1750 | 80 | 1¼" BSP | 626 | 20,8 | 628 | 20,8 | 611 | 20,5 | 570 | 20,1 | 485 | 19,9 | 395 | 19,76 | - | - | 80 |

| 450 | 30 | 1750 | 80 | 1¼" BSP | 917 | 28,3 | 949 | 27,6 | 912 | 27,1 | 841 | 26,8 | 635 | 26 | 445 | 25,4 | - | - | 95 |

| 500 | 37 | 1150 | 100 | 2" BSP | 985 | 36 | 994 | 35 | 968 | 34 | 883 | 33 | 765 | 32 | 578 | 32 | - | - | 110 |

| 750 | 45 | 1150 | 100 | 2" BSP | 1334 | 43 | 1427 | 42 | 1359 | 41 | 1249 | 40 | 1036 | 40 | 824 | 40 | - | - | 115 |

| 950 | 75 | 1150 | 100 | 2" BSP | 1640 | 57 | 1699 | 56 | 1690 | 56 | 1631 | 55 | 1368 | 51 | 1113 | 82 | - | - | 125 |

| 1200 | 110 | 880 | 150 | 2½" BSP | 2294 | 90 | 2345 | 90 | 2251 | 90 | 2090 | 88 | 1716 | 86 | 1359 | 82 | - | - | 190 |

| 1500 | 110 | 880 | 150 | 2½" BSP | 2701 | 105 | 2940 | 107 | 2786 | 106 | 2549 | 105 | 2081 | 100 | 1648 | 97 | - | - | 220 |

| 1800 | 132 | 880 | 150 | 2½" BSP | 3500 | 125 | 3636 | 126 | 3568 | 120 | 3347 | 116 | 2735 | 113 | 1954 | 110 | - | - | 250 |

| Model GDM |

Motor kW |

Speed rev/ min |

Flange conn mm |

Service liquid conn |

660 TORR | 560 TORR | 460 TORR | 350 TORR | 250 TORR | 150 TORR | Service liquid flow rate l/min |

||||||

| m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | ||||||

| 20/2 | 1.5 | 2800 | 32 | 3/8" BSP | 34 | 0.6 | 35 | 0.8 | 35 | 0.9 | 32 | 1.1 | 28 | 1,2 | 19 | 1,3 | 5,9 |

| 30 | 2.2 | 1450 | 38 | 1/2" BSP | 54 | 0.75 | 54 | 0.97 | 54 | 1.19 | 54 | 1.34 | 52 | 1,49 | 42 | 1,49 | 7 |

| 60 | 3 | 1450 | 38 | 1/2" BSP | 105 | 1.72 | 105 | 2.28 | 105 | 2.39 | 105 | 2.54 | 105 | 2,61 | 88 | 2,69 | 12 |

| 85 | 4 | 1450 | 38 | 1/2" BSP | 150 | 2.61 | 150 | 2.98 | 150 | 3.21 | 150 | 3.51 | 145 | 3.88 | 130 | 4 | 16 |

| 100 | 5.5 | 1450 | 50 | 1" BSP | 170 | 3.21 | 160 | 3.73 | 160 | 4.1 | 160 | 4.4 | 160 | 4,85 | 152 | 5,22 | 20 |

| 150 | 7.5 | 1450 | 50 | 1" BSP | 255 | 4.85 | 255 | 5.37 | 255 | 5.97 | 255 | 6.42 | 245 | 6,86 | 220 | 7,46 | 25 |

| 200 | 11 | 1450 | 64 | 1" BSP | 340 | 5.97 | 340 | 6.71 | 340 | 7.46 | 340 | 8.06 | 330 | 8,65 | 300 | 9,33 | 30 |

| 240 | 15 | 1450 | 64 | 1" BSP | 410 | 7.46 | 410 | 8.21 | 410 | 8.95 | 410 | 9.7 | 400 | 10,44 | 360 | 11,19 | 40 |

| 300 | 18.5 | 1450 | 80 | 1¼" BSP | 510 | 8.95 | 510 | 10.82 | 510 | 12.31 | 510 | 13.65 | 490 | 14,92 | 440 | 16,04 | 50 |

| 450 | 22 | 1450 | 100 | 1¼" BSP | 750 | 15 | 750 | 16 | 750 | 17 | 750 | 18 | 730 | 19 | 660 | 20 | 62 |

| 580 | 30 | 1450 | 100 | 2x1¼"BSP | 1000 | 20 | 1000 | 22 | 1000 | 24 | 1000 | 27 | 930 | 28 | 720 | 30 | 70 |

| 700 | 37 | 960 | 127 | 2" BSP | 1250 | 28 | 1250 | 29 | 1250 | 30 | 1250 | 31 | 1200 | 31 | 1100 | 31 | 90 |

| 900 | 45 | 960 | 127 | 2" BSP | 1550 | 36 | 1550 | 37 | 1550 | 39 | 1550 | 40 | 1500 | 41 | 1300 | 41 | 105 |

| 1200 | 75 | 720 | 203 | 2½" BSP | 2000 | 31 | 2000 | 37 | 2000 | 43 | 2000 | 49 | 2000 | 54 | 1800 | 58 | 150 |

| 1500 | 75 | 720 | 203 | 2½" BSP | 2600 | 46 | 2600 | 51 | 2600 | 56 | 2600 | 63 | 2500 | 67 | 2200 | 71 | 175 |

| 1800 | 90 | 720 | 203 | 2½" BSP | 3150 | 55 | 3150 | 61 | 3150 | 69 | 3150 | 76 | 3050 | 82 | 2600 | 87 | 200 |

| 2200 | 110 | 720 | 203 | 2x2½"BSP | 3700 | 63 | 3700 | 72 | 3700 | 81 | 3700 | 88 | 3600 | 95 | 3300 | 100 | 250 |

| Model GDM |

Motor kW |

Speed rev/ min |

Flange conn mm |

Service liquid conn |

660 TORR | 560 TORR | 460 TORR | 360 TORR | 260 TORR | 160 TORR | Service liquid flow rate l/min |

||||||

| m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | m3/h | kW | ||||||

| 20/2 | 2,2 | 3400 | 32 | 3/8" BSP | 50 | 1,0 | 57 | 1,2 | 58 | 1,4 | 58 | 1,6 | 55 | 1,7 | 42 | 1,8 | 5,8 |

| 30 | 2,2 | 1740 | 38 | 1/2" BSP | 73 | 1,4 | 73 | 1,5 | 73 | 1,6 | 70 | 1,7 | 70 | 1,9 | 56 | 1,9 | 9 |

| 60 | 4 | 1740 | 38 | 1/2" BSP | 140 | 2,4 | 140 | 2,6 | 140 | 2,8 | 140 | 3,0 | 136 | 3,1 | 114 | 3,2 | 15 |

| 85 | 5,5 | 1740 | 38 | 1/2" BSP | 197 | 3,4 | 197 | 3,7 | 197 | 4,0 | 197 | 4,3 | 190 | 4,4 | 173 | 4,5 | 19 |

| 100 | 7,5 | 1740 | 50 | 1" BSP | 210 | 4,5 | 212 | 5,0 | 218 | 5,6 | 220 | 6,2 | 218 | 6,5 | 200 | 6,7 | 26 |

| 150 | 11 | 1740 | 50 | 1" BSP | 315 | 6,8 | 318 | 7,1 | 322 | 7,9 | 322 | 8,6 | 317 | 9,1 | 274 | 9,5 | 32 |

| 200 | 15 | 1740 | 64 | 1" BSP | 425 | 9,0 | 425 | 9,3 | 425 | 10,2 | 425 | 11,0 | 416 | 11,8 | 348 | 12,4 | 37 |

| 240 | 18,5 | 1740 | 64 | 1" BSP | 470 | 11,12 | 480 | 11,6 | 490 | 12,7 | 480 | 13,7 | 460 | 14,7 | 405 | 15,5 | 48 |

| 300 | 22 | 1740 | 80 | 1¼" BSP | 625 | 16 | 625 | 16,5 | 625 | 17 | 625 | 17,5 | 580 | 18 | 440 | 19 | 59 |

| 450 | 30 | 1740 | 100 | 1¼" BSP | 940 | 22 | 940 | 23 | 940 | 25 | 940 | 26 | 910 | 27 | 800 | 28 | 75 |

| 580 | 45 | 1740 | 100 | 2x¼ BSP | 1200 | 30 | 1200 | 31 | 1200 | 32 | 1200 | 33 | 1150 | 34 | 870 | 36 | 100 |

| 700 | 45 | 1150 | 127 | 2" BSP | 1400 | 40 | 1400 | 40 | 1400 | 41 | 1380 | 42 | 1350 | 43 | 1150 | 43 | 130 |

| 900 | 75 | 1150 | 127 | 2" BSP | 1800 | 52 | 1800 | 54 | 1800 | 55 | 1800 | 56 | 1800 | 57 | 1485 | 57 | 150 |

| 1200 | 90 | 880 | 203 | 2½" BSP | 2400 | 57 | 2400 | 65 | 2400 | 72 | 2400 | 77 | 2295 | 84 | 2040 | 87 | 220 |

| 1500 | 110 | 880 | 203 | 2½" BSP | 2755 | 71 | 2755 | 81 | 2755 | 91 | 2755 | 98 | 2700 | 102 | 2395 | 107 | 250 |

| 1800 | 150 | 880 | 203 | 2½" BSP | 3300 | 99 | 3300 | 104 | 3300 | 111 | 3300 | 118 | 3160 | 125 | 2805 | 131 | 300 |

| 2200 | 185 | 880 | 203 | 2x2½" BSP | 4400 | 108 | 4400 | 120 | 4400 | 134 | 4400 | 147 | 4320 | 159 | 3750 | 164 | 370 |